Your Reliable Injection Molding Factory in China

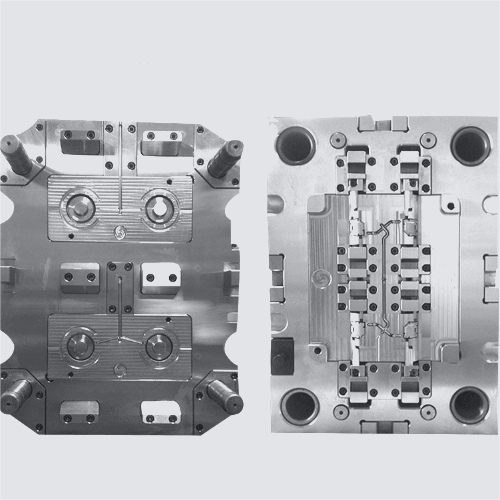

Injection Molding Service

- From design tools and making molds to prototyping and manufacturing, custom your parts to your exact specifications.

- Receive custom-molded prototypes and production pieces crafted to meet your needs.

- Choose from a range of materials including rigid, flexible, and rubber-like plastics, all meeting industry standards.

Request your quote today.