What’s Precision Machining?

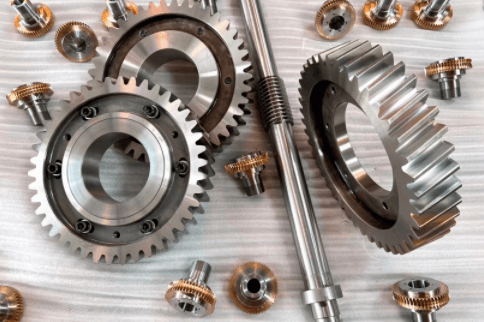

Precision machining is the technology that utilizes computer-controlled machine tools to produce parts with exacting precision. It’s ideal for crafting components with tight tolerances or complex designs.

Skilled machinists or advanced robotics handle precision machining, ensuring versatility in production. CNC machines, often integrated with high-speed robotics, autonomously direct cutting tools across the workpiece with precision. This subtractive manufacturing process starts with a solid block of material, meticulously carving it with precision cutting tools.

Successful precision machining relies on 3 factors.

- Premium cutting tools. High-quality cutting tools delicately shape materials to exact dimensions.

- CNC machines. Advanced CNC machines usually use cutting-edge systems, often with high-speed robotics, guide cutting tools with unmatched precision CNC machining parts.

- The experienced team with high-quality awareness. ONLY the team with high-quality awareness can give you high-precision parts.

There is no doubt that ZXP Tech, recommended by Fortune 500 companies, can meet the above conditions and provide high-precision parts to customers.

Precision Machining Process

After confirming the CAD drawings and the project, precision machining is usually done through a series of similar steps.

- Raw Material Inspection: Ensure raw materials meet our high quality standards.

- Machining: Utilize CNC milling, CNC turning, tapping, drilling, etc all kinds of precision machining technology to meet product specifications.

- Deburring: Smooth out sharp edges and corners.

- Surface Treatment (optional): Apply processes like zinc plating, chrome plating, or nickel plating to enhance corrosion protection and abrasion resistance.

- Inspection: Verify the quality and specifications of machined parts.

- Cleaning and Packaging: Prepare finished products for delivery by cleaning and packaging them.

Precision Machining Materials

There are many raw materials for CNC Precision Machining. Such as bar, tube, solid, and other profiles.

Metal materials for precision machining services:

Carbon Steel and Structural Steel: 1010, 1020, 1045, Q345B, C60 and others;

Spring Steel: 1066, 50CrVA and others;

Tool Steel: M50, M2, A2, D2 and more;

Aluminum Alloy: 2021, 2024, 6061, 7075 and more;

Copper Alloy: C1020, C36000, P31C and more;

Stainless Steel: 201, 304, 316, 316L, 1.4301, 1.4305, 1.4307 and more;

Plastic materials for precision machining services:

- Polyamide (PA)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polymethyl Methacrylate (PMMA)

- Polyoxymethylene (POM)

Other materials:

- Wood

- Glass

- Graphite

Applications of Precision Machining

Precision machining serves as the backbone of numerous industries, enabling the creation of prototypes and final products with exceptional accuracy. You can see a lot of precision machined products in your life. Its applications span various sectors:

- Electronics: Precision machining services can produce complex electronic parts with tight tolerances.

- Automotive: The automotive sector relies on precision machining for crafting intricate gears, engine components, axles, and other crucial parts for vehicles ranging from two-wheelers to airplanes and ships.

- Prototyping: Precision CNC machining is indispensable for producing prototypes across industries, ensuring precise replication of intended designs.

- Medical Industry: With medical technology evolving rapidly, precision CNC machining services play a crucial role in fabricating intricate components for automated tools and surgical equipment, catering to the growing complexity of medical devices.

- Aerospace: The aerospace industry demands many precision machined parts with utmost accuracy, capable of withstanding extreme conditions.

- Defense Industry: Similar to aerospace, the defense sector relies on advanced precision machining for producing rugged components, ranging from weapon prototypes to entire missile systems, meeting stringent quality standards.

FAQ

Precision Machining FAQ

- How can I choose the precision machining company?

It’s very important to choose a precision machining company as a reliable partner.

You can check from experience, capability, quality control, and communication to review the potential suppliers.

- How can I start my precision machining project?

You can send the detailed 3D and 2D drawings to us for Design for Manufacturing analysis (DFM analysis). It’s Free. Do not worry the confidentiality. We value your intellectual property as our life. We can sign the NDA before the drawings are sent.

- Should I insist on choosing the near suppliers for my CNC precision machining parts?

We recommend you choose precision machining suppliers from China. The prices with shipping are still much cheaper than your local suppliers. What’s more, it only takes 3~5 days for shipping. You can get the precision machined products at your home/company.

Conclusion

So now you know the answer to What precision machining is, the precision machining process, precision CNC machining materials, high precision machining applications, like aerospace precision machining, and you know how to find the trustful precision CNC machining suppliers.

If you need a reliable precision CNC machining supplier, get in touch with ZXP Tech, and you will receive a quote within 12 hours.

ZXP Tech Precision Machining Services Video