Rapid Production Turnaround

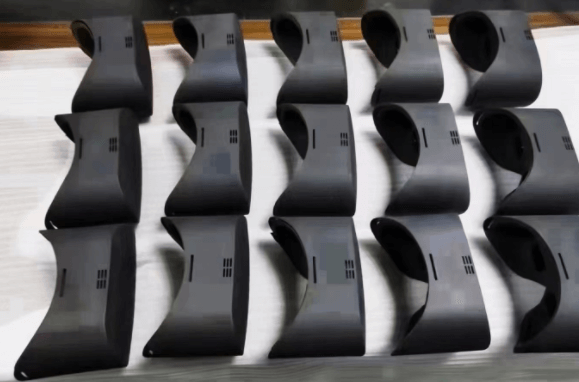

Urethane Casting Services

- Parts Available in as Little as 7 days

- Ideal for Low-Volume Prototyping & Transitioning to Full Production

- Replicates a Wide Range of Production-Grade Thermoplastics

Urethane casting, known as Vacuum casting in the USA and other North American regions, is also referred to as Polyurethane casting. It’s a low-volume manufacturing method that employs a vacuum chamber to create precise and high-quality replicas of master patterns, often crafted from silicone molds. This technique is popular for rapid prototyping and small-scale production due to its cost efficiency, speed, and capacity to replicate intricate details.

Here are the 5 main steps for creating urethane casting:

| Tolerance | ±0.03 mm |

| Minimum wall thickness | 1.5mm~2.5mm |

| Typical Quantities | 20~25 copies/mold |

| Color & Finishing | Customized Colors, Metallic, and texture |

| Typical Lead Time | Up to 20 parts in 10 days or less |

Can I choose Urethane Casting to make overmolding parts?

YES. Elastomeric urethane can be seamlessly molded over metal or plastic components to produce products with a rigid core and a soft surface. Additionally, inserts can be press fitted or glued into urethane parts.

Do the Urethane Casting can make clear plastic parts?

YES. We can do clear plastic parts by the urethane casting process.

Can I cutsom different colors parts by Urethane Casting?

YES. Usually, it’s no problem as long as you give us the specific color numbers.

(All uploads are confidential)

WhatsApp us